S-IVB Third Stage

- Diameter : 21ft 8in (6.604m)

- Height : 58ft 7in (17.8562m)

- Weight(dry) : 33600lb (15.24ton) (include 7700lb Aft.Interstage)

- Weight(loaded) : 265600lb(120.47ton)

- Manufacturer : McDonnell Douglas Astronautics Co. Huntington Beach, Calif.

- Burn time

- 1st burn : 2.75min approx.

- 2nd burn : 5.2min approx.

- Velocity at burnout

- 1st burn : 17500mph approx.(28157.5km/h)

- 2nd burn : 24500mph approx.(39420.5km/h)

- Altitude at burnout

- 1st burn : 115mile approx.(185km)

- 2nd burn : translunar injection

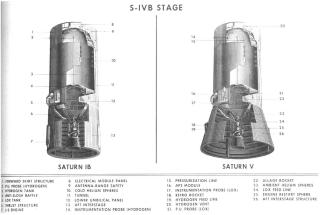

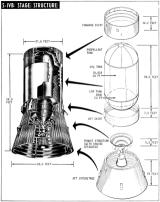

Structure

Forward Skirt Assembly

The extreme top of the body, ring-shaped part to connect IU is Forward Skirt Assembly. This is made from aluminum, and equipped with the environmental conditioning system which cools various an electronic machine, an antenna and them. This environmental conditioning system is controlled by IU. Here is equipped with the two DC28V batterys, too. Two telemetry antennas transmit digital signals that PCM/FM moderated to the ground, the variety information of the stage.

Propellant Tank Assembly

It is a fuel tank, the center of the body is greatly occupied. The top of about 3/4 is the LH2 (Liquid Hydrogen) tank, and the remainder, about 1/4 of bottom part is the LOX (Liquid Oxygen) tank. And, eight circle helium tanks are being installed inside the LH2 tank, for apply pressure to push the fuel out to engines. This tank is made of aluminum alloy, and waffle pattern was cutting down in inside for weight reduction and strength reinforcement. The ring-shaped board called slosh-baffle is being installed inside the LOX tank to prevent liquid oxygen from being choppy during the flight. Tile-shaped fiberglass insulation is stuck inside the LH2 tank. Fuel is poured slow speed at the beginning of injection, to wait for chill down the tank. High-speed injection is done next. Then filled slowly until it becomes 100% at the end. When finished the injection, before launch, kept supplying the fuel that lost by the vaporization.

- LOX

- temperature : -297 degrees Fahrenheit

- pressure : 38-41psia

- LOX Fuel injection speed

- 5% of tank : 500gpm(gallons per minute)

- 98% of tank : 1000gpm

- 100% of tank : 0-300gpm

- LH2

- temperature :-423 degrees Fahrenheit

- pressure : 31-34psia

- LH2 Fuel injection speed

- 5% of tank : 500gpm(gallons per minute)

- 98% of tank : 3000gpm

- 100% of tank : 0-500gpm

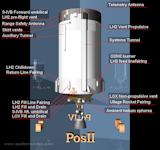

Thrust Structure Assembly

Thrust Structure Assembly is the cone-shaped in the bottom part of the body, equipped with the J2 engine. Engine gimbal system, spare circle helium tank, O2/H2 burner and so on are carried here too. This O2/H2 burner is used for warming up the helium which got cold too much when the second time burn for TLI.

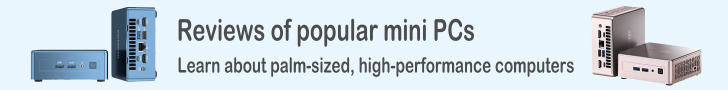

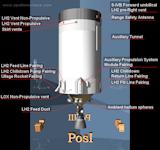

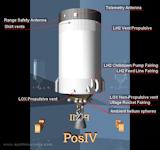

Aft Skirt Assembly

The extreme bottom part of the body, a ring-shaped part to connect Aft Interstage is Aft Skirt Assembly. Two set of posture control rockets (Auxiliary propulsion system : APS), two Ullage Rockets, one DC28V battery and one DC56V battery is carried here. APS is was completely independent rocket system with S-IVB. It has an private liquid fuel tank in that, and can be controlled in 3 axis. Ullage Rocket is solid fuel rocket to increase the acceleration to press fuel inside the tank at the bottom. It ignites before J2 engine jetting, and is jettisoned after use.

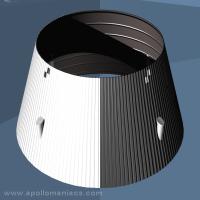

Aft Interstage Assembly

This cone-shaped part is connected smooth aerodynamically between S-IVB and S-II. This part is fixed on S-II and four reverse jetting rockets (Retro Rocket) for S-II are built in.

Jettison

Jettison control unit between S-II and S-IVB is equipped on S-II. This S-II Flight Sequencer transmitt pulse signals to the disjunction device (EBW) which is equipped on S-IVB after three seconds of S-II engine cut off. Then, fire signal of 2300V is sent to the fuse (MDF) from EBW, and jettisoned. Next, four Retro Rocket carried on Aft Interstage are jetted by S-II Flight Sequencer for 1.5 seconds. S-II leaves S-IVB by this action.

Range Safety System

On Forward Skirt, two RangeSafety antennas are carried. When an emergency occurred, this system catch a signal from the ground and starts the spark plug and cleaves LOX and LH2 tank.