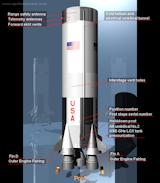

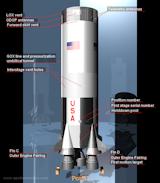

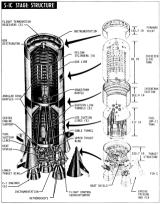

S-IC First Stage

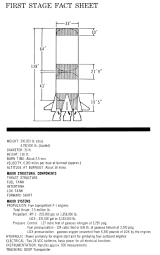

- Diameter : 33ft (10.06m)

- Height : 138ft (42.06m)

- Weight(dry) : 303000lb (137.44ton)

- Weight(loaded) : 4881000lb(2213.97ton)

- Manufacturer : The Boeing Co. New Orleans

- Burn time : 2.5min approx.

- Velocity at burnout : 6000mph(9654km/h)

- Altitude at burnout : 38miles(61.14km)

Structure

Forward Skirt Assembly

Furthermore, ODOP (Offset Doppler Tracking) system to tracking movement of the rocket is carried here. High frequency signal from the ground is received with this ODOP system, then sent back again to the ground. The ground can know the movement of the rocket from doppler shift of the frequency.

With APOLLO 4 and 6, four color film cameras are carried here, make a film of the inside of LOX tank during the flight. The capsule that camera and film are stored is separated 25 seconds after the S-IC separation, parachute is opened and splash down, collected with the help of the signal of radio beacon.

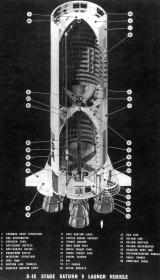

LOX Tank Assembly

331000 gallons (about 1426ton) of LOX (Liquid Oxygen) of -297 degree Fahrenheit are carried here. Through five LOX suction lines, 2000 gallons (about 19ton) of LOXs are supplied to the F1 engine per 1 second in flight. Cut-off sensor is being installed in the top end part of this LOX suction line. When it is detected that LOX disappeared by this, engines are stopped.

LOX is injected from two Fill & Drains located at the bottom of the tank with 1500 gallons per minute until they become 6.5% of the tanks. It is poured at 10000 gallons per minute until it meets 95% when it exceeds 6.5%. Then, it is poured until it is 100% at 1500 gallons per minute at the end.

When temperature of LOX rose, cooling is done by sending the bubble of the helium to the inside of LOX suction line. And, this helium and oxygen, nitrogen are used for pressurize of LOX. 45 seconds before launch, Helium is poured until pressure becomes 26psia through GOX (Gaseous Oxygen) distributor located at the top of the LOX tank from ground equipment. Then, pressurize is done during the flight as a part of LOX is heated by the heat of the engine and returning it to the LOX tank.

Intertank Assembly

This ring-shaped structure is located between LOX Tank and FUEL Tank, and connect those modules. Here is the access door for the maintenance and various connectors called umbilical opening. A LOX outlet for the emergency, pressurize port, electric connector and so on is contained in this umbilical opening.

FUEL Tank Assembly

The fuel used by S-IC is a kind of kerosene called RP-1. 203000 gallons (about 630ton) of RP-1s are carried on this fuel tank. Through 10 Fuel suction lines, 1350 gallons (about 4ton) of RP-1 are supplied to the F1 engine per 1 second in flight. The pipe which makes the bubble of nitrogen is installed in Fuel suction line. Temperature of the fuel is prevented from rising before launch using this pipe. And five LOX suction lines are passing in this tank for supply LOX to F1 engines.

Fuel is injectioned at 200 gallons per minute from Fill & Drain located at the bottom of the tank until they become 10% of the tanks. It is poured at 2000 gallons per minute until it meets 102% when it exceeds 10%.

Pressurize of fuel is done by the helium supplied by four high pressure bottles located in the LOX tank. This helium is sent to the F1 engine once and heated. Then, it is returned to the fuel tank again, and used for pressurize.

And, fuel is used as the fluid power to change the direction of the engines during the flight. Fuel is sent to servo actuator from high pressure fuel duct during the flight.

Thrust Structure Assembly

Range Safety System

This system stops an engine with the command from the ground, burst fuel tank, throw fuel away in the air, in the emergency. When a proper command is received from the ground, redundant Safety Command Receiver stops an engine, fire Shaped Charge, and tank is exploded.