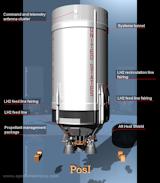

S-II Second Stage

- Diameter : 33ft (10.06m)

- Height : 81ft 7in (24.87m)

- Weight(dry) : 95000lb (43.09ton)

- Weight(loaded) : 1037000lb(470.37ton)

- Manufacturer : North American Rockwell Corp. Space Div. Seal Beach, Calif.

- Burn time : 6min approx.

- Velocity at burnout : 15300mph(24617.7km/h)

- Altitude at burnout : 114.5miles(184km)

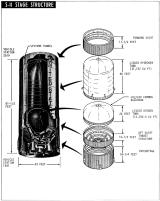

Structure

Forward Skirt Assembly

The LH2 pressurize system, telemetry antennas, and various measuring units are stored here. The telemetry system measures the pressure of the tank, temperature, fuel flow, the vibration of the body, noise, a position, acceleration, and so on. This antennas are being installed on the surface of Forward Skirt flatly, and it is omnidirectional.

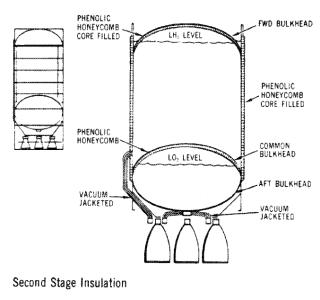

LH2 and LOX Tank Assembly

It is the fuel and oxidizer tank to occupy the center of S-II's own. Fuel is LH2 (liquid hydrogen) of 260000 gallons (153000 pounds) of -423 degrees Fahrenheit, and LOX (liquid oxygen) of 83000 gallons (789000 pounds) of -297 degrees Fahrenheit. The weight of this fuel occupies more than 90% of the all S-II's weight. This tank is made of the light weight aluminum alloy, and the insulation of the special light weight is spread inside. This insulation insulates 500 degrees Fahrenheit betwwen the air and the fuel in 1.5-inch thickness. The top 3/4 is the LH2 tank made of six cylinder shape rings. A bottom part 1/4 is oval shape LOX tank. Systems Tunnel of 60 feet is being installed outside the tank from the top to the bottom. The variety electric cable which connects Aft Skirt with Forward Skirt passes in this.

Purge Subsystem

Before putting fuel in the LH2 tank, air inside the tank must remove oxygen completely. Or, Oxygen is frozen in the LH2 tank, then when a vibration is received, it reacts with LH2 and explodes. Therefore, before the fuel injection, until oxygen is discharged, it is repeated that helium is poured from the ground establishment and exhausted.

Fill and Replenish Subsystem

LOX and LH2 are poured slow speed at the beginning of injection, to wait for chill down the tank. High-speed injection is done next. Then filled slowly until it becomes 100% at the end. When finished the injection, before launch (LOX 160 sec. before, LH2 70 sec. before), kept supplying the fuel that lost by the vaporization.

- LOX

- temperature : -297 degrees Fahrenheit

- pressure : 37-39psia

- LOX Fuel injection speed

- 5% of tank : 500gpm(gallons per minute)

- 98% of tank : 5000gpm

- 100% of tank : 0-1000gpm

- LH2

- temperature : -423 degrees Fahrenheit

- pressure : 31-33psia

- LH2 Fuel injection speed

- 5% of tank : 1000gpm(gallons per minute)

- 98% of tank : 10000gpm

- 100% of tank : 0-1000gpm

Venting Subsystem

Two exhaust valves are set up in each of LOX, LH2 tank. This is opened at the signal from the ground at the time of the fuel injection, and used for removing the gas which vaporized in the tank.

Pressurization

Pressurize of S-II is done by pouring helium from the ground establishment before launch. After the J2 engine start, pressurize is done by vaporized LOX, LH2 by the heat of J2 engine.

Aft Skirt and Thrust Structure Assembly

Aft Interstage Assembly

[Ullage]

An old brewer's term referring to the gaseous zone in a tank above the liquid.

S-IC jettison

After F1 engine stops and S-IC is separated, Ullage rocket motor on Aft Interstage jets for about four seconds. By this action, fuel is pressed against the bottom part of S-II tank, and sent to the J2 engine. After about 30 seconds of the S-IC jettison, Aft Interstage is separated with Ullage rocket motors. As for the separation of this Aft Interstage, extreme precision is required by control. It must be done not to collide with the J2 engine in that with continuing high speed flight. There is only the 3feet (1m) gap between Aft Interstage and the J2 engine. This two-step separation of S-IC and interstage is called "dual plane separation".